In the die casting sector, die failure is an operational cost…

Heat Treatments: Laser Hardening

Laser hardening is a surface heat treatment that increases surface hardness and improves wear resistance, thereby extending the service life of steel components (including quenched and tempered steels).

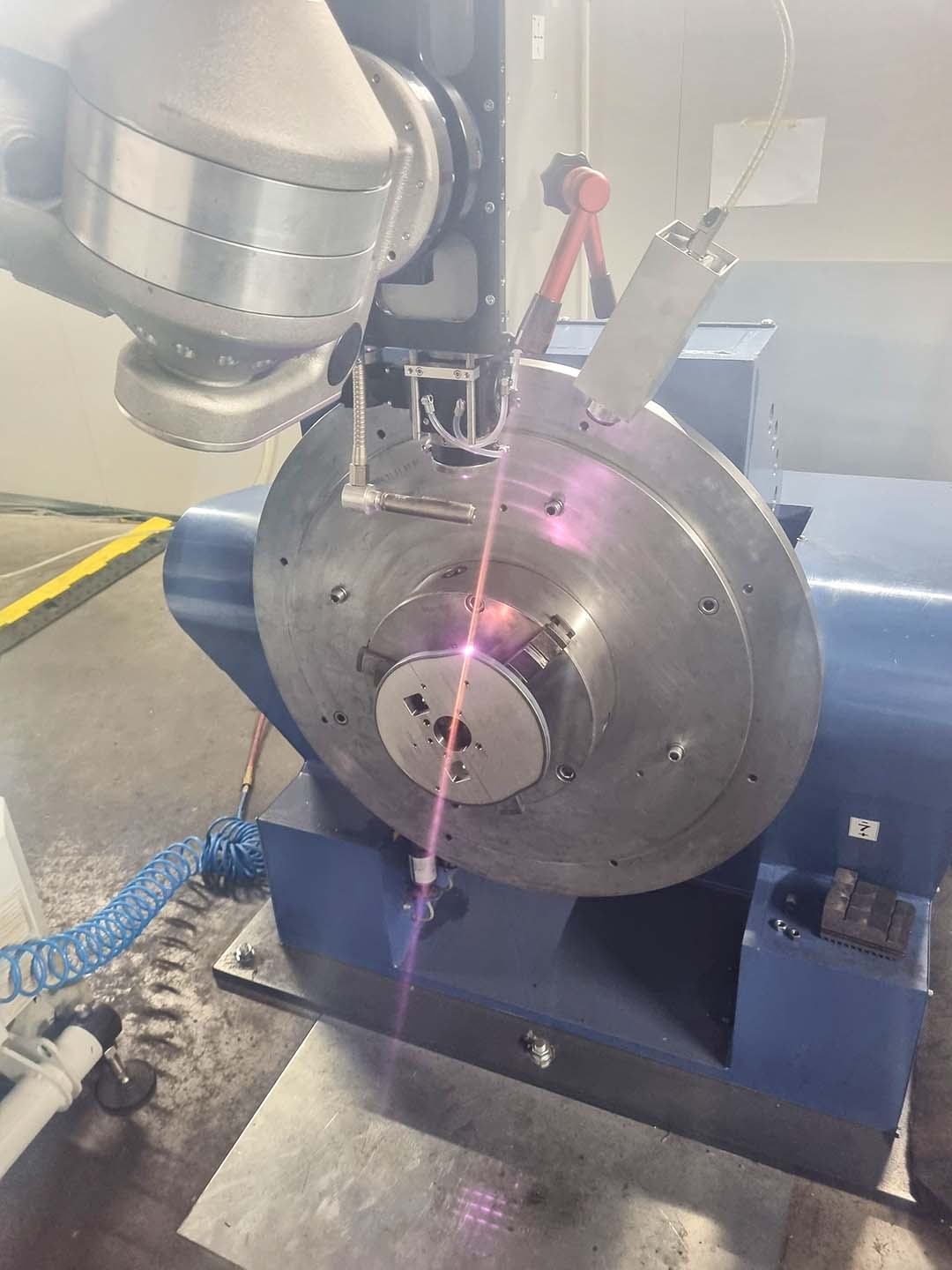

The process uses a high-power-density laser beam to selectively heat the outer layer of the material, ensuring minimal distortion thanks to the absence of cooling fluids.

Key Features

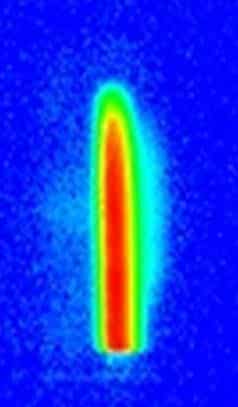

- Adjustable laser beam (5–30 mm) for localized heating

- No cooling liquids: the part cools by conduction

- High precision and instant temperature control via pyrometric sensor

- Virtually no material distortion

Achievable Surface Hardness

This surface treatment is suitable for all steels with a minimum carbon content. The achievable surface hardness depends solely on the carbon content in the alloy:

| Carbon Content | Surface Hardness |

| 0,2 ÷ 0,3 %C | 46 ÷ 55 HRC |

| > 0,3 %C | 55 ÷ 64 HRC |

Advantages of Laser Hardening

- The treatment applies heat only to critical areas, reducing deformation of molds or mechanical parts.

- The pyrometric sensor adjusts the laser beam power in real time.

- No surface swelling and no excess material → no need for post-treatment finishing.

Conclusion

Laser hardening is a highly precise heat treatment that enables localized hardening of steel, ensuring minimal distortion and eliminating the need for post-processing.

It is the ideal solution for components exposed to wear and high mechanical stress, even with complex geometries.

Bonomi Acciai, official representatives in Italy of Swiss Steel Group, supports engineers in selecting the most suitable special steels and heat treatments to optimize component performance, durability, and reliability.

Would you like to learn more?