In the High-Pressure Die Casting (HPDC) sector, heat checking resistance is…

Eddy Current

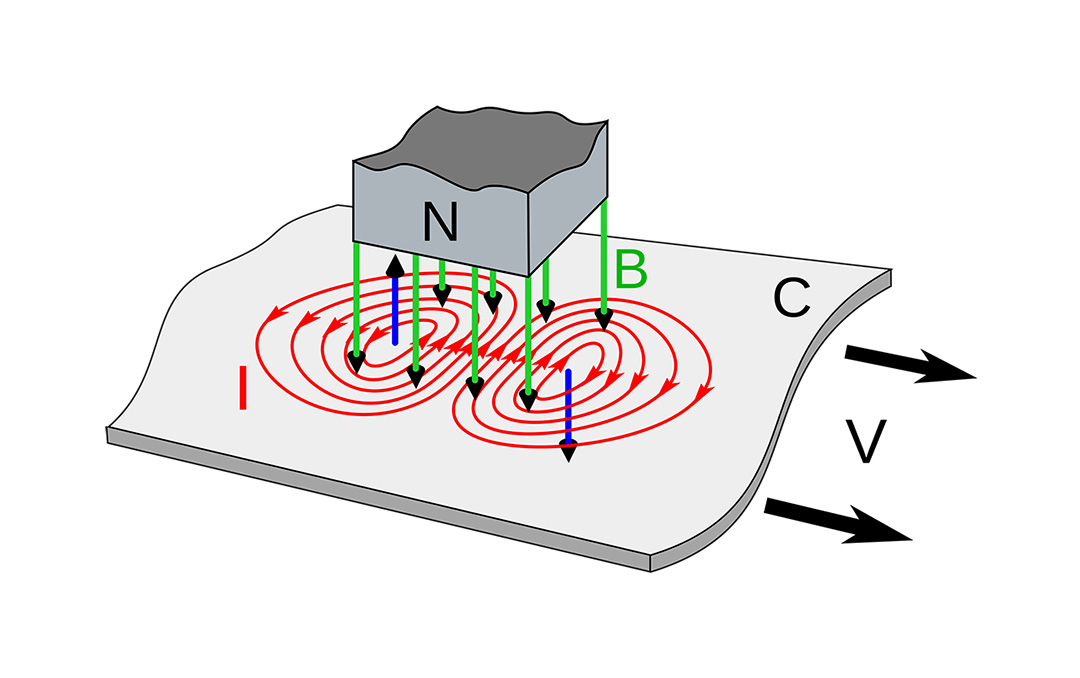

The Eddy Current (or induced current) is a non-destructive testing (NDT) technique that uses an electromagnetic probe to detect surface or sub-surface defects in conductive materials. This technology is widely used in the metalworking industry to verify the quality and integrity of products.

The operating principle is based on the generation of eddy currents when a variable magnetic field interacts with a conductive material. Variations in the distribution of these currents, caused by defects or irregularities, are detected to identify anomalies in the material.

Eddy Current Control Applications.

The Eddy Current technique is widely used in various industrial sectors, including:

- Aerospace: Inspection of critical components such as wings and fuselages.

- Automotive: Quality control on metal components like shafts and bearings.

- Energy: Verification of pipelines and heat exchangers.

- Steelmaking: Identification of cracks, inclusions, or surface defects in steels and metal alloys.

Advantages of the Eddy Current Method.

The Eddy Current technique, a non-destructive testing method, is widely used in various industrial sectors, including:

- Non-destructive: The material remains intact during inspection.

- High sensitivity: Detects small defects, even sub-surface ones.

- Immediate results: Inspection happens in real-time, with no downtime.

- Versatility: Applicable to a wide range of materials and shapes.

- Economical and sustainable: Reduces material waste through accurate quality control.

Types of Detectable Defects.

The Eddy Current technique is ideal for identifying various types of defects in conductive materials, including:

- Surface cracks: Such as fissures or fractures caused by mechanical or thermal stress.

- Inclusions: Impurities present within the material that compromise its quality.

- Corrosion: Detection of eroded or damaged areas.

- Sub-surface defects: Irregularities located just beneath the surface.

- Geometric defects: Non-conforming variations in the material’s shape or size.

The method’s sensitivity allows for the detection of even very small defects, making it a crucial tool for verifying material integrity.

Factors Influencing Effectiveness.

The effectiveness of Eddy Current control depends on several factors, including:

- Material: Materials with high conductivity (like steel or copper) offer more accurate results.

- Thickness: Deeper defects might be less evident compared to surface ones.

- Sample shape: Complex geometries can affect signal readings.

- Temperature: Temperature variations can alter electrical and magnetic conductivity.

- Magnetic field frequency: Higher frequencies improve the detection of surface defects, while lower frequencies are better for deeper defects.

Choosing the right parameters is essential to ensure maximum test reliability..

The Eddy Current Technique: Conclusion.

Eddy Current is one of the most effective non-destructive testing techniques for verifying the quality and integrity of conductive materials. Thanks to thorough testing, even minimal defects can be detected. Bonomi Acciai, the Italian partner of Swiss Steel Group, offers certified special steels that undergo meticulous verifications, ensuring quality and reliability for applications in highly demanding sectors.