In the die casting sector, die failure is an operational cost…

Heat Treatments: PVD Coatings

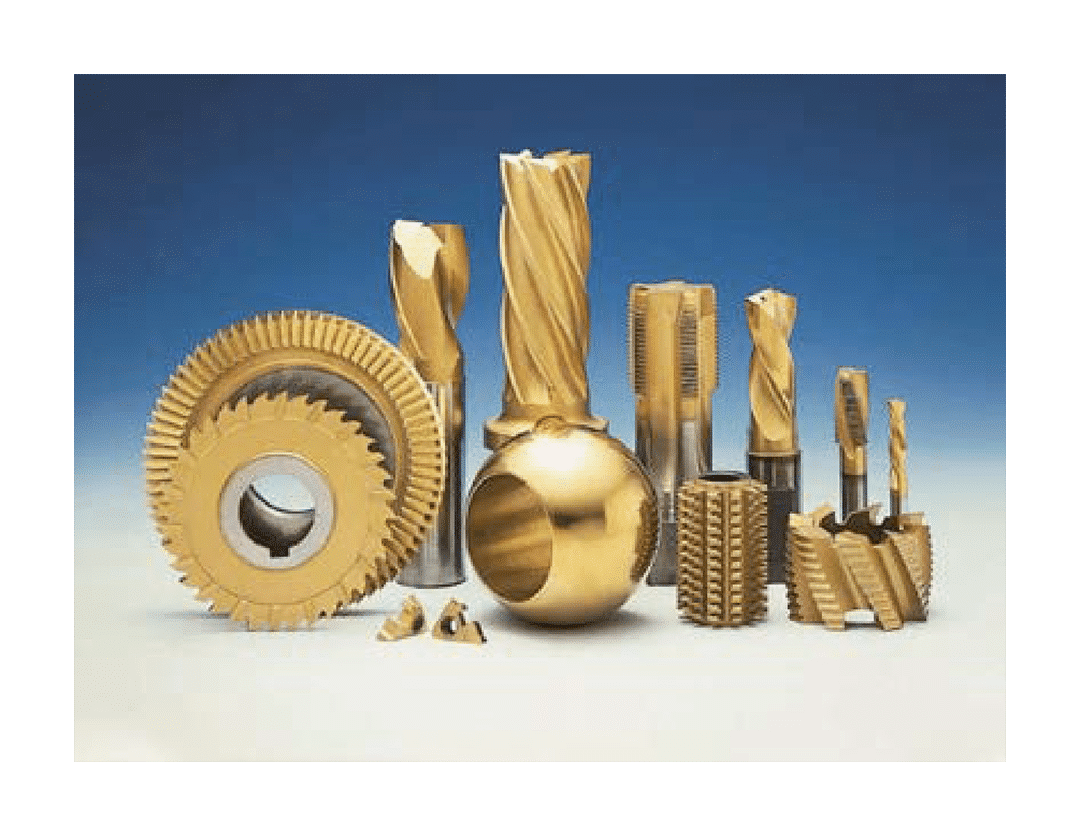

PVD coatings (Physical Vapour Deposition) are thin ceramic surface films, typically just a few microns thick (μm), made mainly of very hard carbides and nitrides of metallic elements such as Chromium, Titanium, Aluminum, Molybdenum, and Zirconium.

These surface layers are formed by evaporating the target materials in a plasma state (under high vacuum), in the presence of gases like Nitrogen, Methane, or others.

Deposition temperatures range from 180 to 560 °C, with coating thicknesses from 1 to 10 μm, and surface hardness exceeding 2000 HV.

Benefits of PVD Coatings

PVD coatings help delay surface damage phenomena such as wear, abrasion, galling, and corrosion.

They improve the sliding behavior between metallic components by interposing a thin, extremely hard layer.

They also act as a solid lubricant between frictional metallic contacts.

Applications

In the plastic injection molding sector, PVD coatings help reduce galling and abrasion.

In die casting applications, the low reactivity of carbides and nitrides with molten metal significantly reduces surface wear, adhesion, thermal fatigue, and corrosion.

Additionally, thanks to their high chemical inertia, PVD coatings offer partial protection from corrosive environments.

Conclusione

PVD coatings provide an effective solution to enhance the performance and durability of metallic components across various industrial sectors.

By reducing wear, abrasion, friction, and chemical attack, these thin ceramic layers ensure higher surface resistance and improved sliding performance—ultimately optimizing the efficiency and longevity of equipment.

Bonomi Acciai, as the Italian representative of Swiss Steel Group, supports engineers in selecting the most suitable materials and PVD coating cycles tailored to specific application needs.

Would you like to learn more?